Days where designing a car took two or more years are slowly moving away. Nowadays, everyone talks about efficiency and speed of managing project deliverables. It is becoming clear that various costs and time cutting methods for OEM Manufacturers play more and more important role in the automotive industry. This trend also affects digital designers. A well thought-out modeling workflow can dramatically improve efficiency and speed of bringing projects to completion. Is there a universal strategy that digital modelers can benefit from?

The Best Modeling Workflow stands for the most efficient strategy of actions that will allow you to produce top level, digital surfacing results. The strategy is a variable that depends on the project phase, and allowable time frame. Analyzing the project situation to gain insight into its progress-to-expected-results ratio will generate a formula for the best workflow.

What is a workflow?

Nowadays, many industries benefit from goodness of digital design. In various industries, modeling workflows may differ. Wikipedia gives a great definition of a workflow. But how to define it from a practical point of view in a digital modeling office environment?

As a prominent modeler you are going to have an advantage by knowing your responsibilities early in the day. You need to communicate targets and clarify with your design manager what you are expected to complete by the end of the day.

Landing your modeling job with industry’s top employers is definitely something to be proud of, but the new challenging job might also bring some degree of uncertainty. After all, it is not going to be only about your modeling skills that will indicate whether you are able to accomplish tasks thrown upon you or not. These days, moving your computer mouse around is simply not enough. Instead, you must learn how to work smart.

To help you with that you need a well though-out workflow. In an automotive industry, it is an indispensable plan of actions during the process of car design. It is about setting your objectives and knowing from the beginning what and how you are going to accomplish them. It is also vital to know how much time you have to achieve them. The strategy workflow will allow you to gain a lot more success, and will boost your productivity far better than you thought was possible.

It is more to it than that. The plan will not only allow you to speed up your work, but also will make your environment more comfortable, and your results more predictable.

Best Workflow Variables

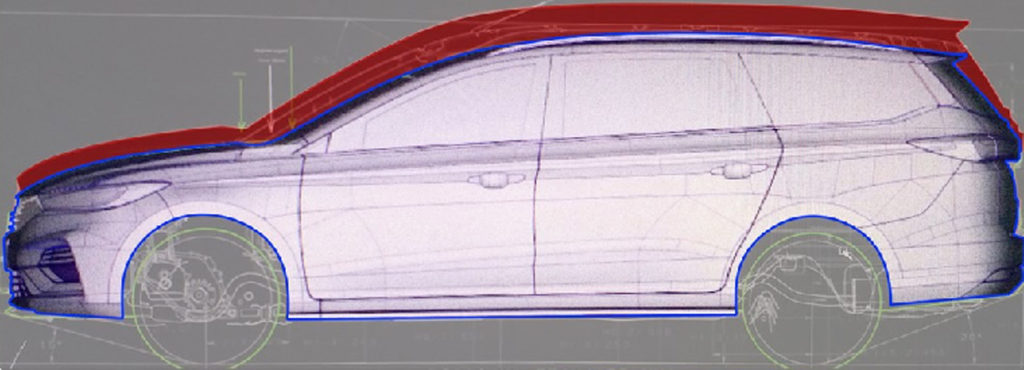

Design manager is breathing down at your neck. You are to produce good quality surfaces to encapsulate the design intent. He or she is coming for you in the evening, and wants to see some decent overall form and some cool ideas that were impossible to get done on paper. In this situation you need to know how to behave, how to communicate, and how to verbally promote and state targets of the day that are within your reach. In this sketch modeling stage nobody will blame you for leaving off opened geometry or not achieving certain continuity within model’s topology. Proportions, volumes, stance are the most crucial qualities at this moment. It will take many iterations of pulling, pushing, stretching of the surfaces to reach a consensus.

You should use the given time to go back and forth between 2D sketches and 3D design, trying to capture and maintain that ‘uniqueness’ in your model. At this stage work is done quickly and roughly without worrying about all of the technical aspects of surfacing. The principle is to surprise your audience with some extraordinary ideas. You also have an opportunity to go a step further and propose some interesting modeling solutions that must be within the ‘boundary’ of the design.

Highlights and quality can be forgotten and completely ignored. When you focus just on the design your artistic ego takes over and you are able to come up with some cool stuff. Suddenly you can treat your digital modeling package just like a polygonal clay manipulation software, and just let it follow and fulfill your ideation role without all the technical which craft.

Other 3D applications might still be in the game to assist you in modeling, such as Speedform, or Maya. Similarly, output surface quality will be low, but results will be produced fast. Leaving off some unfinished topology is perfectly OK, therefore it is called the sketching, because it is supposed to be just rough and light without any commitments. Don’t get stuck on one detail, but instead take a break and go to other areas to progress the model.

Arrange your working time. Don’t burden yourself with too much to do, but also don’t undervalue your abilities. Keep your attitude well-balanced. Explain how much time particular tasks will take. Don’t let others make you feel like you underperform. Don’t let others undervalue your efforts.

Clay is a medium to perform magic. You can touch it, feel it and form it to your liking. From time to time, clay modelers will be physically reworking your design, by heating up the milled clay model and reshaping it. Revisited form will be scanned, and obtained data will come around for you to perform reverse engineering. It is a perfect way to remove some unwanted, sometimes ugly volume.

Working with clay isn’t always the case thought. At Bugatti, there is no clay modelers, everything is done digitally. Under these circumstances, digital modelers, although craving for it, are not able to see a real deal model for a long time. That close interaction between human and a full size machine is missing, which might be painful. Although digitization leaped a huge progress in car design, seeing a full size models of your own and simply getting excited by the ability of just standing close to it is still needed.

Tackle communication obstacles. It might take you some time to get used to the original, never seen before design idea or to try and error while building the model. It is important that you convey your concerns and fears that might affect your speed earlier than later.

Arrange your hot keys so you don’t have to constantly peep at your keyboard. This can not only break your rhythm, but also hurt your eyes. If you can’t conveniently fit all relevant tools on your keyboard buttons, just use orderly arranged marking menus.

Modeling for Production

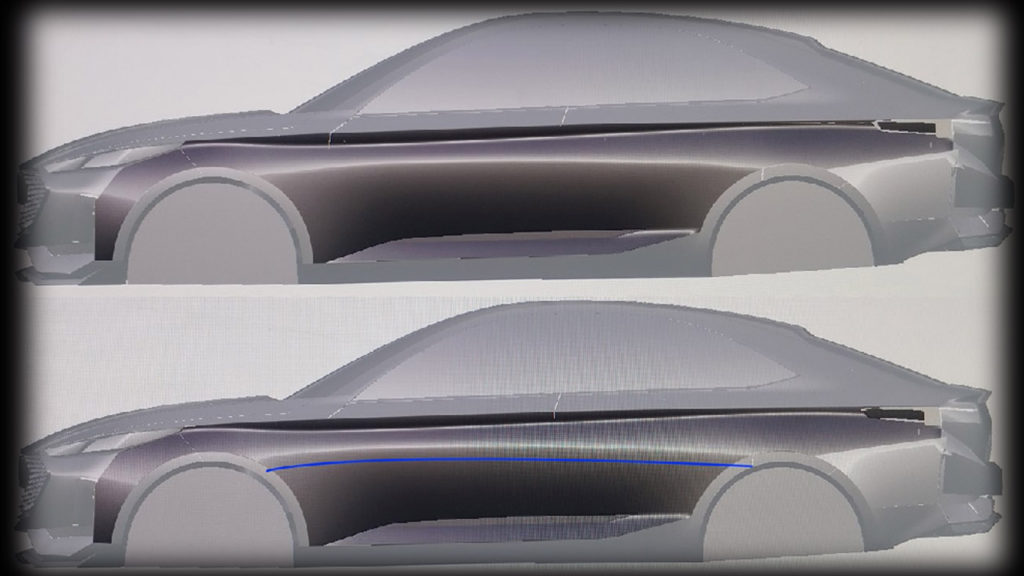

Tesla Cybertruck is a perfect example of a design that has very little styling. Its proportions might be alright, but its finish is very rough. It looks like it went through substantial amount of proportion modeling without any finessing to the design. Instead, it was moved straight to the technical surfacing for production. The car encapsulates the engineering package, but might not meet expectations as to cohesive theme and cohesive design.

At this stage, you become an engineer, and get to encounter other engineers a lot more than before. The design is pretty much settled and matured. Here is where you hear terms: ‘B surface’ and ‘wall thickness’ for the first time. Draft angles and overall boundary dimensions are examined by engineers. The greenhouse curvature for side window free obstacle winding-down, panel gaps and flanges, radii and fillets will also be subjects to scrutiny. Pedestrian safety, and aerodynamic requirements are somewhat less tangible requirements that are purely achieved by trying and failing and trying again.

Technical Surfacing Class A

First of all: congratulations to you! You received the A classing job, which means you are good. You should be proud of yourself and eager to crack on. Now, it is just you, the model and a long evening. After cranking up the tolerance presets for more stringent setting for A class production, you are ready to take on the whole geometry once more. All ‘unfinished businesses’ in your 3D model are coming back at you and demand completion. A lot of precise manual manipulations usually takes a lot of time but are worth the effort. Fine tuning of the Control Vertices became your bread and butter. To measure your progress, you perform various forms of surface evaluations including reflections, zebra stripes, comb curvature plots. Remember! Your design opinion is secondary, so don’t change it at this point. At this stage you have all rights to take your time and not sacrifice quality. 99% of design managers are very tolerant of giving plenty of time for A class surfacing, so you might have even time for a cup of coffee.