Today’s computer technology is truly transformative. In industrial and automotive design, new innovations are no longer limited by engineering constraints. Designers and engineers can now work together seamlessly, creating products that excel in both function and form. This is made possible through Computer-Aided Industrial Design (CAID).

CAID is a digital modeling process that integrates both the functionality and aesthetics of a product. It builds on traditional CAD, expanding its capabilities to meet the visual and design needs of modern product development.

What is Computer Aided Industrial Design?

CAD has come a long way since its early days in the 1970s, when 3D capabilities were limited to basic digital versions of hand-drawn designs. Over the following decade, breakthroughs in programming and computer science transformed CAD, opening the door to a wider range of design possibilities.

The emergence of CAID has further revolutionized product design by combining the efficiency of manufacturing with the demand for visually striking products. This integration has resulted in creations that not only excel in performance but also engage and captivate end-users.

If you would like to know more about CAS, click: Computer Aided Styling – Visually Appealing Digital Modeling

One of the earliest fields where industrial design made a profound impact was automotive design. The sophistication of handcrafted coach-building quickly influenced the entire car industry, setting a standard for elegance and style. As the demand for unique design grew, it extended beyond automobiles to everyday products. Today, with CAID, even the smallest details of industrial design receive the highest level of attention, allowing ideas to evolve and reach their full potential..

What is the difference between CAID and CAD?

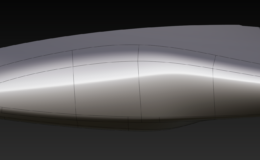

CAD provides a simpler approach to digital modeling but is often limited to solid block modeling, which can be quite restrictive. In contrast, CAID utilizes surfaces, NURBS, or polygons, offering a far more powerful and flexible toolset.

Think of CAID as the artist’s tool and CAD as the engineer’s. CAD is excellent for establishing accurate proportions and basic forms early in the 3D modeling process. As the design progresses, CAID focuses on the visual and functional details, while CAD adds the engineering precision needed for manufacturing. The synergy between CAID and CAD ensures a smooth transition from concept to production.

For more info on Digital design and Automotive Modeling click: How CAS helps products stand out (Computer Aided Styling)?

In the right hands, CAID can unlock a designer’s full creative potential, pushing the boundaries of what’s possible. However, mastering CAID software can be challenging, often requiring years of hands-on experience to truly harness its power.

The product design and development process with CAID follows a carefully structured methodology. It begins with 2D sketches, which are then converted into precise curves. These curves serve as the foundation for creating surface quilts. While the process itself is straightforward, it often demands close collaboration between engineers, designers, and modelers—working together to strike the perfect balance between creativity and practicality.