Computer Aided Styling as a 3D modeling tool to make models more attractive

“In the realm of industrial 3D digital design, you’re navigating a field ruled by intangibles. As digital design becomes increasingly complex, the creation of more intricate and elaborate designs is being empowered by Computer Aided Styling, or CAS.

Advanced computer technology enhances our ability to bring ideas to life digitally. When CAS digital modeling reaches its peak potential, it can significantly enhance a product’s aesthetic appeal, leading to higher sales. This raises the question: Can CAS modeling truly create stunning designs that sell themselves without the need for clever marketing or tricks?

Absolutely, it can. With CAS, the only limit to your product’s artistry and appeal is your imagination! This is why CAS is increasingly utilized throughout all stages of product development. From the initial spark of an idea to its final embodiment, CAS provides detailed design reviews and enhances every step of the process.

For even more info on CAS click: Computer Aided Industrial Design CAID | 3D CAS Product Modeling – Digital Design Services

The CAS modeling approach excels at generating numerous iterative shapes from simple geometric forms. Currently, it still relies heavily on the heuristic decisions of individual designers. However, with the right user, CAS becomes incredibly flexible and easy to control.

How did CAS evolve?

Computer Aided Styling (CAS) refers to the virtual design development process, involving the modeling of objects in 3D software based on data from various sources like sketches, verbal descriptions, or tactile data such as point clouds.

These 3D designs are utilized across nearly every industry imaginable. For example, the design of car bodies and parts has become increasingly digitized through 3D modeling, enabling faster and more efficient product creation than ever before.

The main challenge in using CAS for industrial design is translating the designer’s vision into manufacturable data while preserving the initial creative essence, often referred to as the “zinc”. These starting points frequently take the form of rough CAS models, also known as 3D digital sketches.

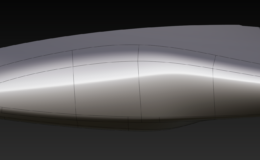

Compared to more intricate designs, a CAS model can be created relatively quickly, based on sketches and even just ideas from designers. CAS models are lightweight files because they utilize degree 2 and degree 3 surfaces built upon a curve structure. These curves can be as simple as degree 2, but for more complex lines, degree 5 curves are also available.

In What Industries Can Computer Aided Styling Be Utilized?

Until now, CAS has primarily been used in automotive design studios, but that’s about to change. CAS is becoming increasingly prevalent in industrial product design studios of all shapes and sizes, transforming the way designs are created and refined.

In industrial product design, modelers need to form a closed volume early in the creation process. CAS provides the ideal combination of freedom and efficiency, allowing designers to quickly and effectively create models whenever needed.

Closed model files can be exported and sent to CNC milling whenever they’re ready. Once transmitted, the model is crafted from clay over an armature made of wood and polyurethane. After forming the synthetic clay mold, a clay modeler makes specific adjustments to refine the design. Once corrected, the model is scanned back into digital form. This .STL, or Mesh Data, file then serves as a foundation for the 3D modeler to further develop the design.

The models created can also be “living” models, or SHARP models. This means the surfaces display points of intersection, known as theoretical intersections, with no radii or fillets applied. This allows for quick changes without extensive updates to the tertiary geometry. It’s important to note that when rounds or fillets are added to surfaces, they can significantly alter the primary geometry.

Understanding the Challenges of CAS Modeling

Many industries using the CAS process are increasingly replacing traditional form-finding with clay or industrial plasticine. These physical renderings are now being supplanted by 3D digital surface modeling, allowing for real-time evaluation of digital data.

Throughout the development process, the 3D model’s status is frequently assessed to ensure it meets the designers’ aesthetic requirements. Simultaneously, other teams verify that it satisfies all manufacturing and engineering standards. Even after the model is fully developed, the CAS model can be continuously refined by professionals, addressing both its technical and aesthetic aspects.

The CAS process offers numerous advantages to designers across various industries. It significantly aids in creating models based on design data, provides a wide range of product variants, and allows for revisiting older versions with more cost-effective modeling. However, evaluating designs on a screen can sometimes be more challenging than with classic physical modeling. This difficulty arises from artificial virtual lighting, scale distortions on the monitor, unusual viewing angles, and the inherent two-dimensionality of the computer screen.

The trend of going fully digital and completely abandoning traditional clay modeling for styling purposes is definitely on the rise..

CAS is increasingly being used to produce models of all sizes, from scale models to full-sized prototypes. In the past, the modeling process was done entirely by hand, relying on the expertise of highly-skilled clay sculptors. These detailed sculptures served as the main reference for the design. Today, computers play a crucial role at every stage of creation, often eliminating the need for clay sculptors altogether..

Computer Aided Styling – Timing and Craftsmanship

The primary advantage of CAS lies in its balance of time and craftsmanship. Simply put, CAS enables the rapid creation of accurate 3D digital models with less effort from skilled modelers. When executed properly, these digital models retain both the design intent and an exceptionally high level of craftsmanship.

In the early phases of design, polygon models are often used. Polygon modeling doesn’t require surfaces to be rendered, making it easier to make changes without backtracking. These models are incredibly useful for design modifications and serve as highly accurate references for further development. Typically, a CNC program can take data from the polygon model and create a fully-milled physical industrial clay model within just a few days of the initial 2D sketch.

Depending on its quality, the geometry generated from polygonal modeling can serve as a reference at various stages, from initial construction and preliminary investigations to concept creation and series production.

With the immense aid of specialized visualization programs, animations, and films generated from CAS modeling, product development cycles are rapidly shortening. Currently, real-time visualization is primarily used for design decisions and interactive applications like games and computer configurators.

Despite minor setbacks and intangibilities, it is increasingly clear that the most concept-efficient future for the design industry lies in the digital realm. 3D software and CAS modeling offer incredible innovations to industrial designers across all sectors, continuing to revolutionize the time it takes to design a product, regardless of industry.

CAS is the Future of Industrial Design

CAS modeling offers incredibly flexible and innovative approaches to product design. These methods significantly reduce the time it takes for businesses across all industries to bring their products from conception to completion. Additionally, these innovations enhance the potential for creative and artistic ideas to be fully realized.

Proper CAS modeling doesn’t sacrifice hands-on craftsmanship; instead, it optimizes it, reducing the time needed to transform an industrial designer’s initial ideas into a 3D product. Industrial clay modeling from CAS data can still be used for physical evaluations when necessary. Embracing CAS modeling for digital product design now will pay off later, as it drastically reduces the time required to turn extraordinary and extravagant ideas into physical reality.